Dates of signing contract / commissioning :

August 30th,2004/Jan.26th, 2006

Contents of project:

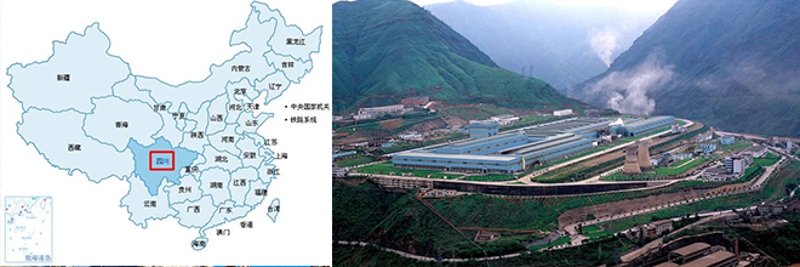

This Coke Dry Quenching (CDQ) project will match with new No.1 & No.2 coke oven batteries for Panzhihua Iron & Steel Company. In this project, new No.1 and No.2 coke oven plant had included 2x 55 coke oven batteries with chamber height of 6m.The coke production of new No.1 & No.2 coke oven batteries had been 1.141Mt/a (130.25t/h).Considering about intense operation of coke oven battery, the project had adopted JNG90-1 CDQ and the capacity of CDQ had been145t/h. When annual inspection or stoppage occurred, wet quenching system had been in operation. The scope of CDQ project had included CDQ boiler system (81t/h CDQ boiler with 4.85MPa and de-aerator & feed-water pump station ,etc), bag house system for CDQ ,comprehensive electric room, water supply system, general layout, external pipes including velocity and pressure reduction station.

Features of major design:

-CDQ chamber

The CDQ chamber, which is positive pressure cylindrical vertical brickwork, has a shaft kiln structure.

- Primary dust collector

The primary dust collector is the gravity settlement tank type de-dusting device, which is used to remove coarse coke fine contained in the circulating gas.

- Secondary dust collector

The secondary dust collector adopted is the multi-cyclone type separating dust collector which is suitable for CDQ process to further separate small sizes of coke fine from the circulating gas. In this way the abrasion of coke fine to the blade of the circulating fan will be reduced.

Scope of contracting:

ACRE had been responsible for this project based on Engineering + Procurement and Construction (EPC).

-red hot coke conveying system, CDQ device, boiler facilities

-gas circulating system, heating power system, electrics system, etc

-automatic control, coke conveyer system, architecture work, equipment procurement & installation engineering in the battery limit for steam pressure reduction station of CDQ project

- Architecture, structure, roads, firefighting and Telecommunication, etc.

- all construction work, etc

Project Highlights:

In this project, ACRE had defeated successfully Beijing JC Energy & Environment Engineering Co., ltd (BJCEEE) and won the copper key award of China Survey and Design Association for contracting projects during the 4th session.